Electroplating Lab Facility for Quality Control at Klein Plating Works, Inc.

KPW employs a full-time staff of highly knowledgeable personnel dedicated to analyzing and maintaining all of its processes in its in-house laboratory. The plating process is multi-faceted and in some cases extremely complex. Every cleaner, acid, rinse and plating solution needs continuous monitoring and adjustments to ensure they remain within tightly controlled parameters. Additions must be frequently made as bath constituents are depleted during production. Just one out-of-compliance step in the entire process can lead to plating failures. To minimize this, KPW has invested heavily in state-of-the-art technology and techniques that help ensure accuracy, repeatability, and process control.

Some of the lab technology and practices used include:

Some of the lab technology and practices used include:

- Inductively Coupled Plasma (ICP) Elemental Analysis to accurately measure the amount of metals and elements in processes to an accuracy of parts per billion

- Digital monitoring and recording of vital bath characteristics such as pH and temperature

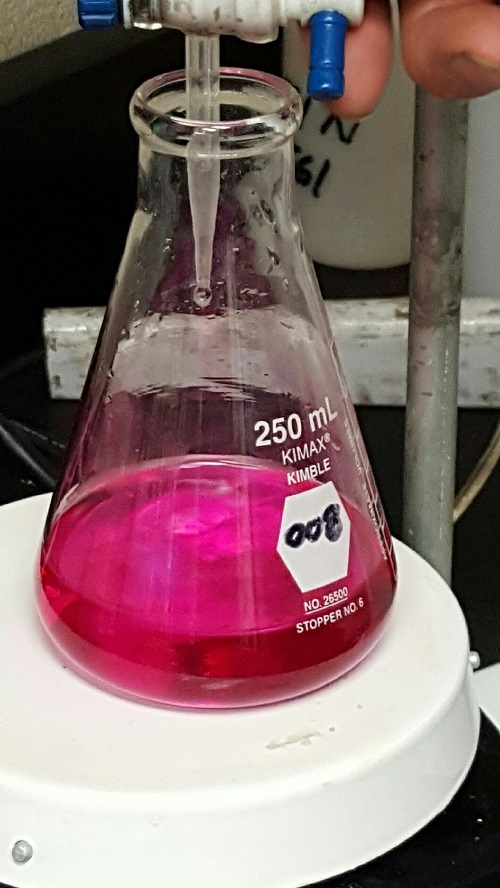

- Daily titration schedules

- Daily Hull cell testing

- Hardness and purity testing of deposits performed by outside vendors

- Continual bath component additions based on digitally controlled amp/hour meters and charts

- A repetitive schedule of bath purification and maintenance

- Proprietary software that catalogs, details procedures, and statistically

trends all bath parameters - An internal system that removes a non-conforming process from production until it is remedied

If you do not see the testing procedure you require or have any quality assurance questions, please contact us for additional information.

Klein Plating Works has done an outstanding job for us in the past and I know that I can count on them for future orders.

Klein Plating Works has done an outstanding job for us in the past and I know that I can count on them for future orders.